200

More than 200 product design patents

100

More than 100 novel and fashionable styles

At the intersection of art and home decoration, DYM has been weaving a fascinating tale of creativity and craftsmanship. Our journey is filled with the vibrant hues of passion, dedication, and innovation, dedicated to establishing a captivating and unique metal trim art brand.

DYM specializes in the design, development, and production of trim and edging lines, pioneering over a hundred new and trendy styles suitable for various ceramic tile surfaces. We take pride not only in the multitude of designs but also in holding over twenty product design patents. Our products go beyond mere decoration; they embody the realization of interior design principles, seamlessly merging functionality with aesthetics.

More than 200 product design patents

More than 100 novel and fashionable styles

Every DYM product represents a dedication to quality, durability, and artistic expression. From elegant silhouettes to intricate embellishments, our team engages in the daily craft of starting with a trim strip. It's not just about simple design but the meticulous refinement of each trim strip, the subtle blending of tones and shape. We constantly innovate, striving for perfection in every detail because we believe a beautifully crafted decorative trim can truly achieve the extraordinary, forming captivating works of art.

DYM attests to the enduring power of passion and creativity, along with the belief that everyone should live in spaces that inspire and elevate. We aspire not only to excellence in design and craftsmanship but also to infuse each product with inspiration and sophistication, making it a ubiquitous geometric art piece within spaces.

DYM DECOR is not just a manufacturer of decorative trim; it is a creator that complements and enhances the style of every space.

2 factories

7 years of production and R&D experience

Stable market in 50 countries and regions

200 experienced employees

Production Machines

Monthly Output

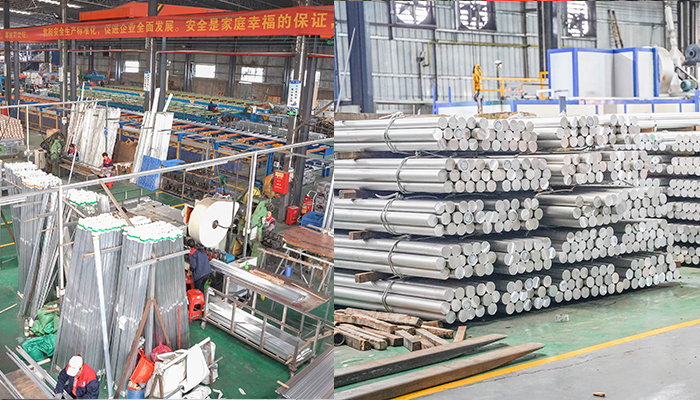

The Chinese factory is located in Foshan, covering an area of 20,000 square meters. The factory is fully equipped with advanced production lines and technical equipment. It has 4 production workshops and 20 production lines. Our China factory has efficient production capabilities and can handle the demand for large-scale orders. There are 100 skilled workers in the factory, and their exquisite skills and efficient work attitude provide reliable guarantee for the manufacturing of products.

The Vietnam factory is located in Bac Giang,. This modern factory is equipped with advanced production equipment. The Vietnam factory includes one-stop production processes such as extrusion, bending, spraying, and oxidation. Eight professional production areas focus on different types of aluminum profile products.

We have established a strong market position in the United States, Canada, Germany and other European countries. As an OEM-based manufacturer, we cooperate with some well-known brand building materials supermarkets around the world to provide them with high-quality aluminum profile products. Our products are popular in the international market, providing customers with superior design choices and reliable quality.

At DYM, our primary goal is to achieve collaboration and satisfaction among relevant stakeholders while meeting legal and regulatory requirements. Since our establishment, we have adopted a quality management system based on ISO 9001 standards, with a focus on comprehensive management and risk assessment to ensure our quality philosophy permeates every aspect of our organization.

We utilize metrics from our quality management system to determine, compile, and analyze relevant data, verifying the applicability and effectiveness of our quality management system. Continuous assessment enables us to identify areas for ongoing improvement, believing that through this process, we can provide products and services that continually meet or exceed expectations.

DYM believes that by applying and maintaining our quality management system, we can achieve several benefits, including commitment to our customers, ensuring the safety of our products and services, continuous improvement, assistance in enhancing overall company performance, and gaining a competitive advantage in the market.

Our commitment is reflected through the continual improvement of quality and maintaining close relationships with stakeholders. We strive to uphold our promise of delivering exceptional products and services.

To ensure our products and services not only meet requirements but also comply with applicable legal standards, we are dedicated to guaranteeing the safety of our products and services.

Every DYM employee bears the responsibility of maintaining and enhancing service quality as part of their workplace activities. We emphasize employee training and establish effective communication channels to ensure the correct exchange of information among various departments, fostering teamwork.

Sales Department

Sales Department Design and R&D Department

Design and R&D Department Production Department

Production Department QC Department

QC DepartmentWe deeply understand our customers' needs and put customer satisfaction first. We strive to provide solutions that exceed expectations and build long-term relationships.

We understand the nuances of global markets and have the flexibility to understand and adapt to market trends, regulations and cultures in different regions. This enables us to provide our customers with building material solutions with an international perspective.

Working across different countries requires efficient collaboration and coordination. Our team focuses on teamwork and communication to ensure smooth information and efficient collaborative work.

We dare to face the challenges of the construction industry and improve design and construction efficiency through the application of innovation and digital technology. We are at the forefront of industry change.

In our projects, we not only consider the aesthetics and functionality of building materials, but also pay attention to factors such as energy saving, environmental protection and social sustainability. We lead the development of sustainable construction with a high degree of environmental and social responsibility.

We demonstrate a high degree of flexibility and adaptability to changing market conditions and project needs.

We focus on ongoing education and training for our team to ensure we are always up to date with the latest technology, industry trends and best practices. This allows us to remain competitive in the industry

We use advanced technology and equipment to improve production efficiency, reduce energy consumption and waste generation, use automated, intelligent, and digital production lines, and use energy efficient lighting and air conditioning systems.

We use environmentally friendly raw materials such as recyclable aluminum and other metals, as well as non-toxic paints and glues to reduce harm to the environment and human health while conserving resources.

Our perpetual goal is to ensure that every one of our partners, suppliers and distributors meets our ethical, environmentally, and socially conscious standards, encouraging sustainable practices throughout the supply chain.

We have implemented a strict waste management system to separate, collect, treat, and recycle the solid waste generated in the production process to avoid polluting the environment while also creating economic value.

We encourage employees to use new energy vehicles and have charging points on our premises. Establish paperless documentation and communication systems to reduce printing and paper waste.

We actively participate in social welfare activities such as afforestation, energy conservation and emission reduction, and environmental advocacy to raise environmental awareness and action among our employees and jointly build a green planet.