What are the key benefits of DYM's punching process for tile trims?

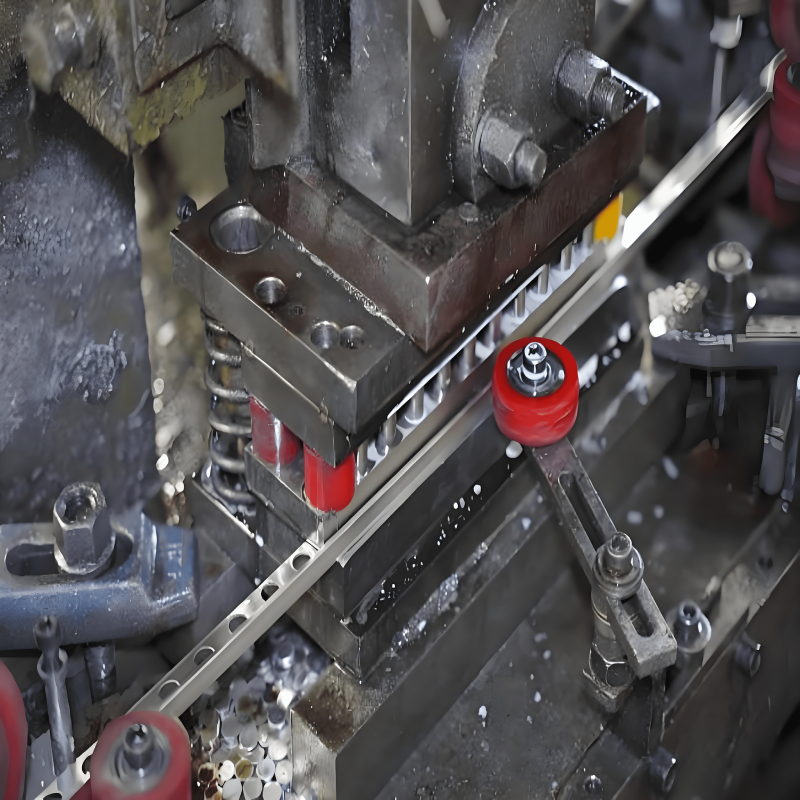

DYM, a distinguished leader in the tile trim manufacturing industry, proudly announces a groundbreaking advancement in its production capabilities—the introduction of an innovative punching process that is set to redefine industry standards and elevate the tile finishing experience.

DYM has long been synonymous with precision and quality in tile trim solutions, and the newly implemented punching process marks a significant leap forward in efficiency, design possibilities, and overall manufacturing excellence.

1.Unprecedented Precision:

DYM's state-of-the-art punching process delivers unparalleled precision in crafting tile trims. The technology ensures consistent and accurate cuts, allowing for intricate designs and details that meet the highest standards of craftsmanship.

2. Versatile Design Possibilities:

The punching process opens up a world of design possibilities for architects, designers, and contractors. DYM can now create a diverse range of shapes, patterns, and sizes, providing clients with customizable options that cater to the unique requirements of each project.

3. Efficiency Redefined:

By integrating this innovative punching technique, DYM has optimized its manufacturing process for efficiency and speed. This not only allows for quicker turnaround times but also enhances overall production capacity to meet the demands of large-scale projects.

4.Streamlined Production:

DYM's commitment to excellence extends to the entire production chain. The punching process streamlines manufacturing operations, reducing waste and optimizing resource utilization, aligning with DYM's dedication to sustainable and responsible practices.

5.Enhanced Durability:

The punched tile trims exhibit enhanced durability and structural integrity. The precise cuts and shaping achieved through this process result in tile trims that not only look exceptional but also stand the test of time, meeting the rigorous demands of various applications.

CEO expressed excitement about the technological leap, stating, "Our new punching process is a testament to DYM's unwavering commitment to innovation and excellence. We believe it will not only meet but exceed the expectations of our clients, setting a new standard in the tile trim manufacturing landscape."

lAbout DYM:

DYM is a leading tile trim manufacturer recognized for its commitment to quality, precision, and innovation. With a history of delivering exceptional solutions, DYM continues to push the boundaries of what is possible in tile finishing, ensuring clients receive unmatched products and services.

lWhy choose DYM:

ØWith more than 20 years of rich experience, we can meet diverse design needs.

ØMade of high-quality aluminum material to ensure long life and durability.

ØContinuous innovation of tile trim with modern technology to provide the best solutions.

ØHigh-quality professional customer service to provide you with the best experience.